A Engemasa pode participar da cadeia produtiva de todos os setores industriais. Hoje estamos presentes em diversos setores, colaborando com o crescimento do país e firmando parcerias internacionais.

A Engemasa pode participar da cadeia produtiva de todos os setores industriais. Hoje estamos presentes em diversos setores, colaborando com o crescimento do país e firmando parcerias internacionais.

A Engemasa pode participar da cadeia produtiva de todos os setores industriais. Hoje estamos presentes em diversos setores, colaborando com o crescimento do país e firmando parcerias internacionais.

A ENGEMASA tem completo domínio metalúrgico de seus produtos e está pronta para vencer os desafios, atendendo o mercado com fundidos estáticos e centrifugados, forjados e serviços de usinagem.

Todos produtos são fabricados com as mais exigentes normas do mercado nacional e internacional. Nosso sistema de qualidade é certificado pela ISO 9001 e auditado pela SGS.

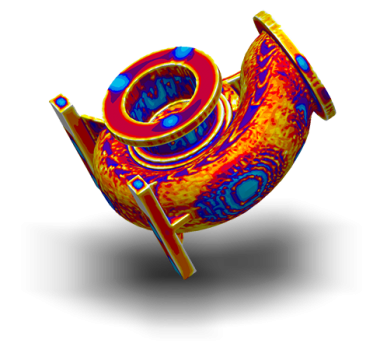

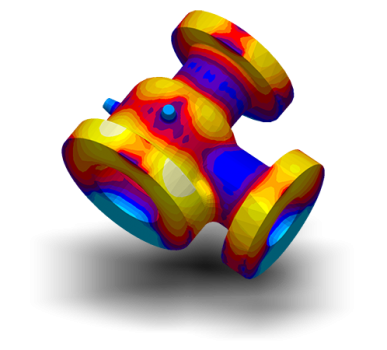

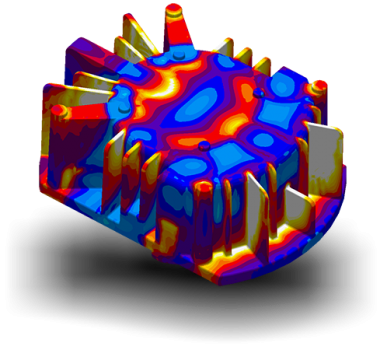

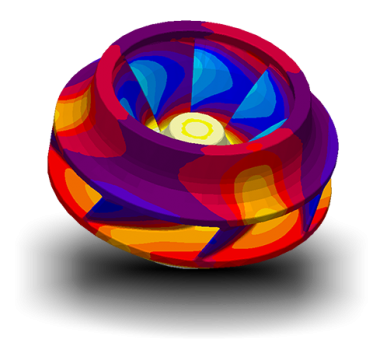

O Software Magma, de última geração permite projetos com alto grau de precisão. A ENGEMASA é uma das poucas empresas brasileiras a possuir esta tecnologia.

A ENGEMASA investe em pesquisa interna e externa, contando com parcerias com as melhores universidades e institutos do país, no desenvolvimento de ligas especiais, visando alto desempenho nos produtos que fornece.

A simulação do processo de fundição auxilia no design do fundido, permitindo que os engenheiros avaliem a sua “fundibilidade”, propriedades finais e custos estimados durante a fase de concepção do produto.

“Feliz aquele que transfere o que sabe e aprende o que ensina” (Cora Coralina)

A Engemasa tem compromisso com a educação, pois ela proporciona a base que mantem os pilares da qualidade de nossos produtos.

Possuímos parcerias com as Universidades do município e estamos desenvolvendo ações para com a sociedade.

Acreditamos o potencial humano, e buscamos colaborar com o desenvolvimento educacional do município.

A ENGEMASA melhora continuamente seus processos e busca novas soluções para reduzir impactos ao meio ambiente, apoiando-se assim no Triple Bottle Line (desenvolvimento economicamente viável, socialmente justo e ambientalmente adequado).

Ao utilizar aparas e retalhos de ferro e aço como matéria prima de nossos produtos, a empresa desempenha importante papel de recicladora, reduzindo a exploração dos recursos naturais e contribuindo para a redução da geração de resíduos sólidos.

Areias de Fundição (ADF) constituem o principal resíduo da empresa, visto que a mesma é utilizada para a confecção de todos os moldes das peças fundidas. Encontrar soluções para o reuso desse material tem sido um dos maiores desafios relacionados à sustentabilidade na ENGEMASA. Análises laboratoriais internas garantem a qualidade da areia após o processo de regeneração mecânica, permitindo o retorno da areia ao processo produtivo.

Desde 2015 a ENGEMASA participa do Carbon Disclosure Program (CPD), programa para a divulgação de emissões atmosféricas, e a cada ano que passa fornecemos um número maior de informações ao programa, promovendo uma relação de transparência com nosso stakeholders.

Considerando que nosso maior patrimônio são nossos colaboradores, possuímos um Programa de Educação Ambiental (PEA) a fim de promover a conscientização de todos quanto às questões ambientais e aos impactos antrópicos no ambiente em que vivemos.

With the watch back inside the case, the bezel was polished to restore the shine, and a new crystal fitted. The original crystal was mineral glass and had a strange profile. wdf replica https://www.watchesreplica.is/ I couldn t find a suitable mineral replacement so I had to use an acrylic crystal instead, which is no bad thing as it will be much easier to polish out the scratches when the inevitable biffing against a door jamb occurs.