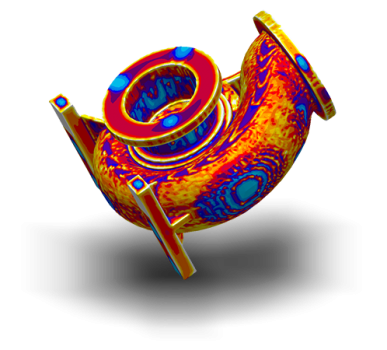

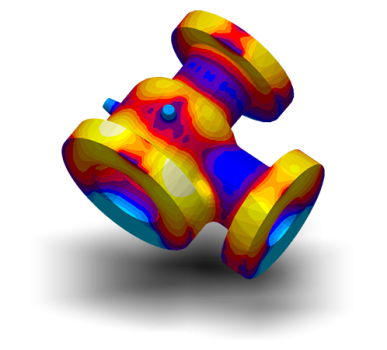

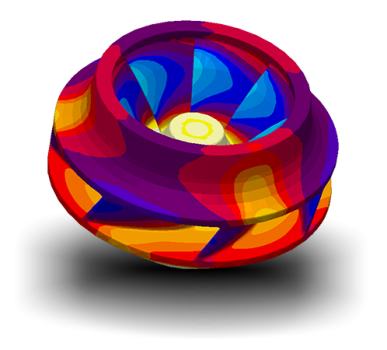

The casting process simulation helps in designing the casting, permitting engineers to evaluate its “castability”, final properties and estimated costs during the conception phase of the product. Predicting potential casting defects in this phase results in an expressive gain for the final quality of the product.

SIMULATION SOFTWARE

Casting process simulation with the MAGMA during the design phase of the product:

enables advances in innovation since it allows economic feasibility of different designs.

identifies any potential defect in advance through filling and solidification simulations.

allows designers to optimize projects, assuring the desired material properties, without the need of excessive safety margins, that is, many times the weight of the casting can be reduced.