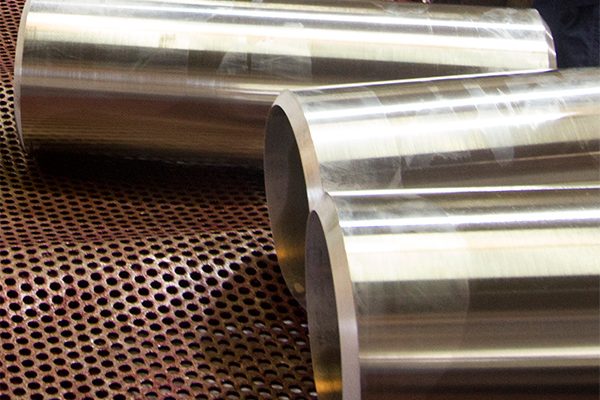

ENGEMASA produces materials to meet the most demanding work conditions in harsh environments, where the materials are subject to corrosion, high temperatures, abrasive work conditions or even a partial or total combination of these.

QUALITY

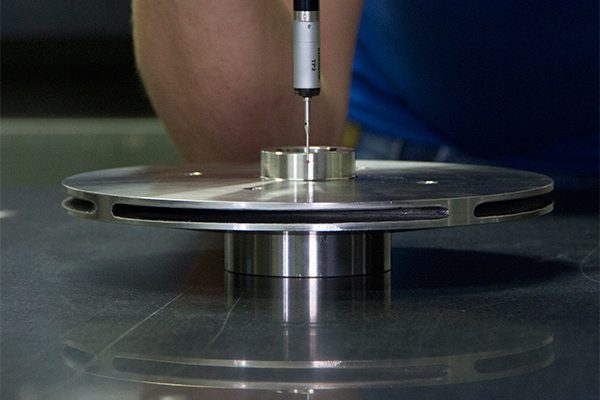

With that in mind, our quality control starts from the receipt of the materials into our facilities, passing through all phases of the manufacturing process until the delivery to our clients, in addition to our post-sales technical assistance.

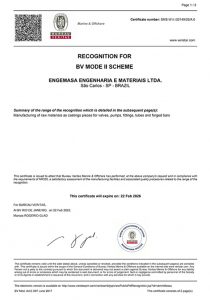

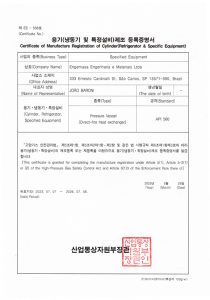

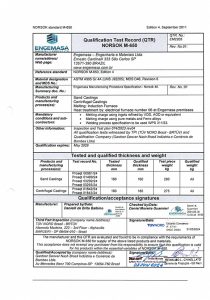

As a pioneer company to be qualified by the strict Petrobras Quality Assurance system back in the 80s, ENGEMASA is SGS ICS Institute (ISO 9001:2000) and the RWTUV Institute (AD 2000 Merkblatt W 0) certified. That assures that our materials comply with the most demanding standards of the domestic and international markets, giving our clients the necessary conditions to compete with an increasingly globalized economy.

We also count with a wide training program and upgrading of four collaborators through courses and lectures to keep them continuously up to date with the newest technologies and quality assurance procedures.

Below the Database and Certificates awarded to ENGEMASA for its recognized quality:

Quality Policy

To provide raw or machined castings and by-products, aiming the technical requirements of national standards and market expectations. Engemasa’s senior management is committed to providing the necessary resources for the continuous improvement of the management of its processes, products and services.