Non-Destructive Testing (NDT) are techniques used in the inspection of materials and equipment without permanently altering their physical, chemical, mechanical or dimensional properties. They are used to detect and evaluate discontinuities (defects), control quality and ensure the reliability of material or equipment.

The most common tests are direct and indirect visual tests (boroscopy), dye penetrant, magnetic particle, ultrasound, radiography, dimensional, PMI (positive material identification), hydrostatic, etc. In this post we’re focusing on radiographic testing!

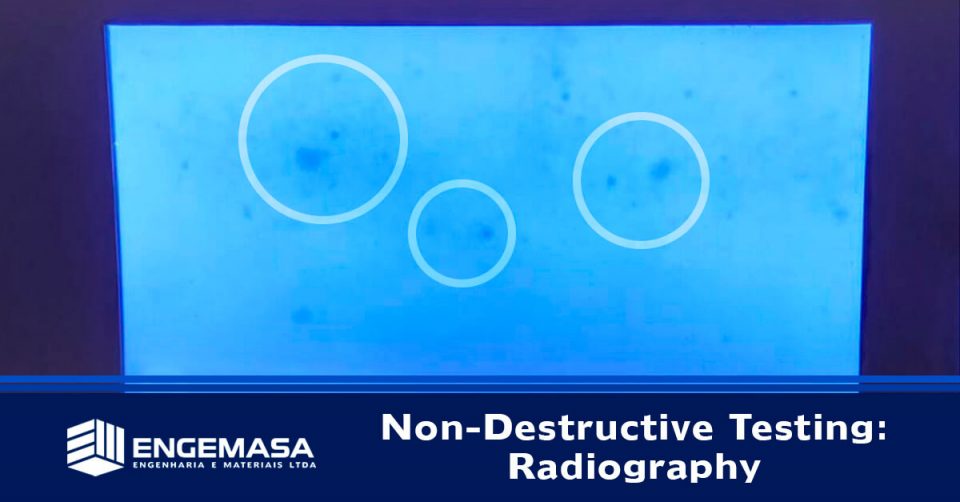

Radiographic testing is a non destructive technique that relies x-rays or gamma rays sent through an object or casting to detect internal discontinuities (defects).

Similar to medical use, a radiation source is used and a film is placed between the casting and radiation source, with the difference between diffraction and radiation absorption being recorded on film or digitally.

Gamma rays are the most common for castings inspection, being generated by Iridium source (thin thickness, below 100 mm) or Cobalt (thickness, above 100 mm).

Engemasa has qualified inspectors per ASNT and ABENDI and has two bunkers to perform radiographic test according to your specification, contact us for more details!