ENGEMASA seeks to evolve in its TECHNICAL and HUMAN capacity

aiming to obtain more QUALITY and PRODUCTIVITY in the segments it operates.

BUSINESS

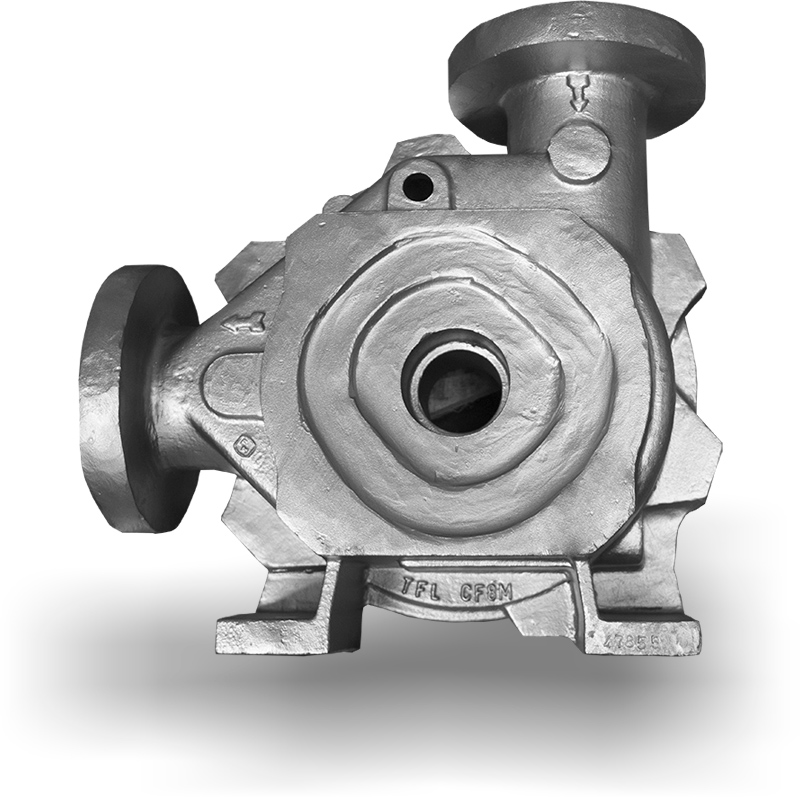

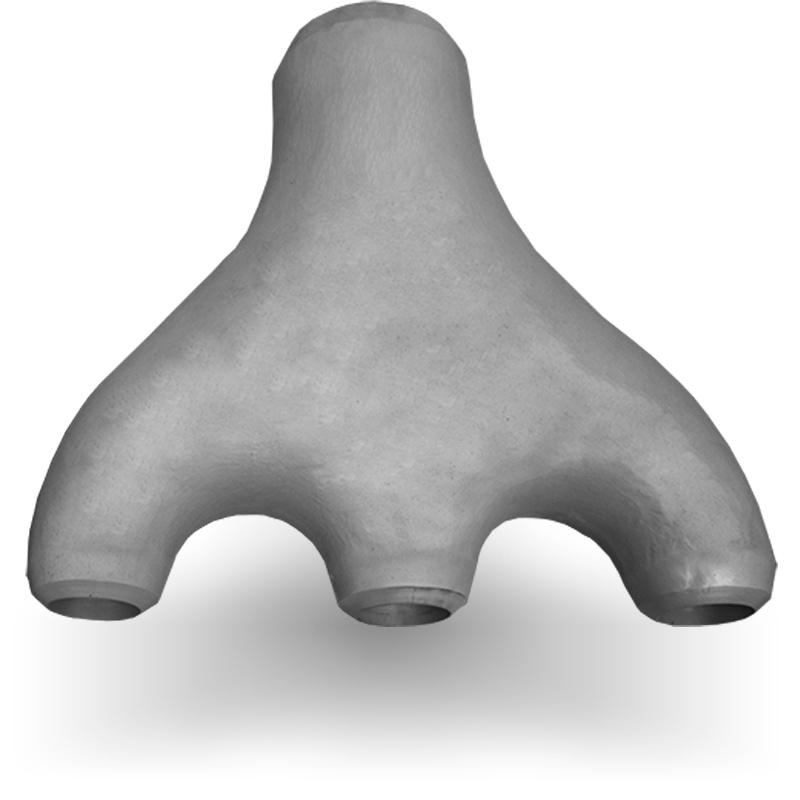

Static Castings

Excellence in the Process

The parts cast by ENGEMASA are produced according to the most modern casting process. Being able to have from 0.5 kg to 4500 kg of ‘clean’ piece, the pieces are produced within the most rigorous control of chemical composition, heat treatments necessary to verify the adequate metallographic structure, dimensional examination, destructive tests and tests by magnetic particles, liquid penetrant, ultrasound, gammagraphy.

Melting Furnace

The melting furnaces are air induction which with the application of selected raw materials and the addition of suitable deoxidizing elements allow the production of alloys containing low carbon and dissolved gases, ensuring that the tubes produced by centrifugation are free of inclusions, micro and microcracks.

Pioneer in Quality

ENGEMASA produces seamless pipes centrifuged to meet the most severe conditions of corrosion, high temperatures and abrasion. For this, our quality control starts from the receipt of the raw materials in our facilities, being present in all stages of the manufacturing process, until delivery to our customers.

As one of the first companies to be qualified by the rigorous PETROBRAS Quality Assurance system back in the early 80’s, ENGEMASA is an ISO 9002 certified company by the German institute TÜV. This assures that our materials meet the most demanding standards in the domestic and international markets, providing our clients the necessary conditions to compete in an increasingly globalized economy.