ENGEMASA seeks to evolve in its TECHNICAL and HUMAN capacity

aiming to obtain more QUALITY and PRODUCTIVITY in the segments it operates.

BUSINESS

Petrochemical

Flexibility for the development of new alloys

Since its foundation, Engemasa has sought to develop high value-added materials with excellent oxidation, carburizing and highly abrasive performance. With complete know how and a team of specialists, Engemasa has large experience and in-depth knowledge of special alloys and super alloys resistant to high temperatures. In addition to the already developed and consolidated materials, Engemasa presents great flexibility for the development of new alloys in order to meet and exceed the most diverse needs and requirements of customers.

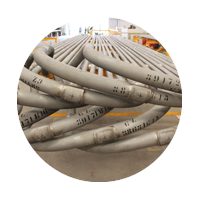

Since 1986 Engemasa has also been gaining worldwide recognition through the manufacture of static castings and centrifuged tubes for application in coils and pyrolysis furnace components for the production of ethylene and reform furnaces for petroleum refineries and ammonia production.

During the assembly of the coils, the components undergo rigorous inspection steps and performance tests, ensuring that all requirements are fully met.

In the aftermarket, Engemasa counts on a specialized team to provide serpentine monitoring services in operation to prevent failures, offering an analysis of metallurgical degradation of the components in relation to the phenomenon of carburization and creep (stretching).

Engemasa seeks to constantly improve its products with its customers, developing new methodologies for the performance and behavior analysis of materials and components in operation, with the main objective of increasing the useful life of the petrochemical furnaces.

Our Advantages

Coil lifting device allows observation and control of the arrangement and accommodation of the coils in an upright position prior to field installation.

Patented technology for measuring and controlling the level of carburizing of the tubes in operation.

Material of high performance and chemical composition that decrease coke formation inside the tubes and consequently the carburization, thus increasing the life cycle of the coils.

High precision tube bending machine.