ENGEMASA seeks to evolve in its TECHNICAL and HUMAN capacity

aiming to obtain more QUALITY and PRODUCTIVITY in the segments it operates.

BUSINESS

Centrifugal Castings

Excellence in Process

The centrifugation process counts as one of ENGEMASA’s most versatile processes, where it is possible to produce seamless tubes with diameters ranging from 55 to 350 mm and up to 4.5 m in length. The tubes are produced under the most rigorous control of chemical composition and centrifugation parameters, in order to provide adequate metallographic structure, dimensional examination and non-destructive tests.

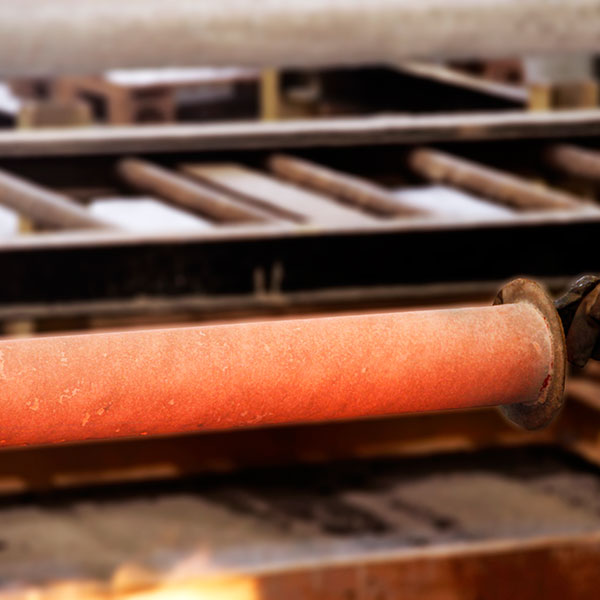

Melting Furnace

The melting furnaces are air induction which with the application of selected raw materials and the addition of suitable deoxidizing elements allow the production of alloys containing low carbon and dissolved gases, ensuring that the tubes produced by centrifugation are free of inclusions, microvoids and microcracks.

Pioneer in Quality

ENGEMASA produces seamless pipes centrifuged to meet the most severe conditions of corrosion, high temperatures and abrasion. For this, our quality control starts from the receipt of the raw materials in our facilities, being present in all stages of our manufacturing process, until delivery to our customers.

Research & Technology

ENGEMASA has more than 30 developed metal alloys that can be applied in equipment resistant to high temperatures, corrosive atmospheres, carburizers and oxidizers. Most of these steels were developed in partnership with the largest universities in the region (USP-São Carlos and UFSCar), both nationally and internationally recognized for their post-graduate programs in Materials Engineering.

In addition to the exchange of knowledge, the partnership with the universities allows Engemasa to perform scanning electron microscopy, dispersive energy spectroscopy, dilatometry and differential scanning calorimetry analysis and creep test,.

We also have an extensive program of training and retraining of our employees through courses and lectures so that they are always up to date with modern technologies and quality assurance procedures.